|

|

|

Micropositioning and Fiber-AlignmentThe probing of optical semiconductor devices often has to be done with an optical fiber positioned at the point of highest optical emissivity or sensitivity. For this purpose we have developed our micropositioning systems MIPO - consisting out of fast piezo translators, electronics and a real timer controller. Depending on the application, the systems achieve alignment times of a few hundred milliseconds with a position accuracy of up to 1Ám. The supply of the device under test (DUT) and the measurement at the position of optimal light coupling is normally done with precise standard test equipment as laser diode controllers and SMUs. However, during the alignment process the outputs of the DUT are bypassed to our own electronics in order to gain short measurement times. The mechanical parts are adapted to the specific application of our customers, depending on the available dimensions and the size of the search window. Below we describe some field tested sample applications. Moreover, we have built further solutions, that are used by our customer, including systems with light coupling from the bottom side of the wafer or integration of optical lens systems.

|

Specifications

|

|

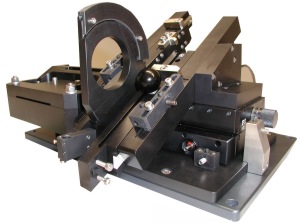

System for the fully automated positioning of an optical fiber during wafer probing. Mechanics are optimized for applications with very small distances between contact pins and optical active area of the DUT. Therefore, fiber holder and HF contacting system are mounted onto two separate, parallel mounted brackets. The position of the fiber is aligned to the optimal position for coupling the laser beam of a vcsel into the fiber. The search algorithm is implemented at a intelligent real time PC card.

Specifications

|

|

Home | Company | Products | Download | Contact Us | Imprint | References | (c) 2003 BAUER Engineering GmbH - Last Updated: 20.03.2007 / Greger